What makes us special?

- Artisanal Craftsmanship: The skilled artisans in our tannery bring a level of expertise and attention to detail that sets our products apart.

- Innovative Techniques: Our tannery might be at the forefront of adopting new technologies and techniques in leather production, leading to unique and high-quality goods.

- Sustainable Practices: If our tannery prioritizes eco-friendly methods, such as responsible sourcing and waste management, it reflects a commitment to environmental stewardship.

- Ethical Sourcing: We might go the extra mile to ensure that the leather we use comes from ethical and responsible sources, contributing to a more sustainable industry.

- Quality Assurance: Rigorous quality checks at every stage of production ensure that only the finest leather products leave our tannery.

- Global Reach: Our tannery’s products may be known and sought after on an international scale, indicating a global appeal and reputation for excellence.

- Customer-Centric Approach: Prioritizing customer satisfaction through exceptional service and attention to feedback can lead to a loyal customer base.

These unique qualities collectively contribute to what makes our leather tannery special, distinguishing it in terms of quality, craftsmanship, sustainability, and its connection to heritage and community.

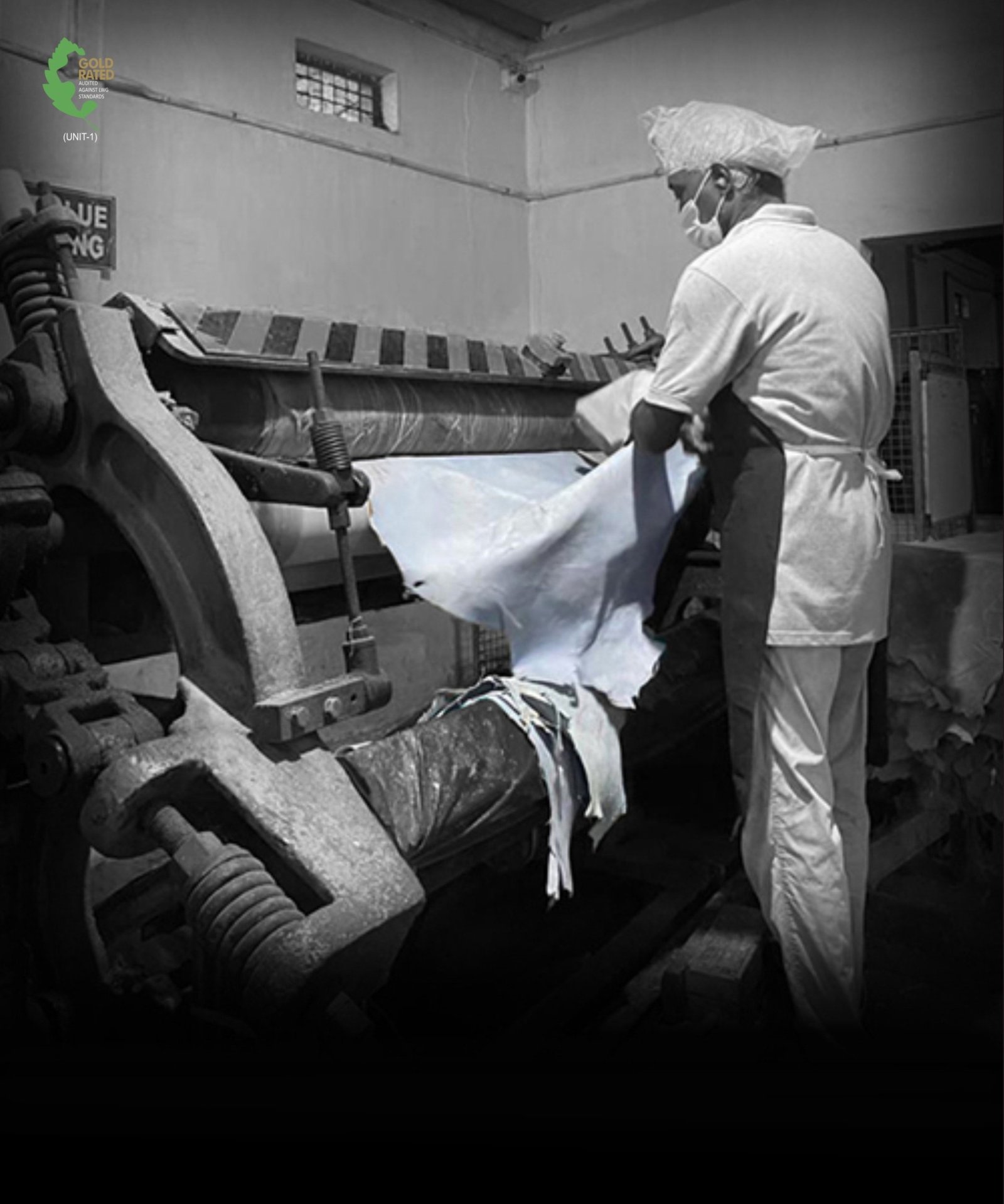

Leather Fleshing Process: Perfecting Leather’s Texture and Quality

Leather fleshing is a crucial stage in leather processing, where the excess fat, flesh, and subcutaneous tissue are skillfully removed from the animal hide. This intricate process not only refines the leather's thickness but also enhances its overall quality, making it supple, durable, and ready for various applications.

Leather buffing section

The process involves carefully sanding or buffing the leather surface to remove imperfections, enhance its appearance, and prepare it for dyeing or further treatment.

Wetblue inspection

Wetblue inspection is a critical step in the leather production process. It involves a thorough examination of the wetblue skins, which have undergone initial tanning but have not yet been fully processed into finished leather. During this inspection, trained professionals carefully assess the quality and condition of the wetblue material.

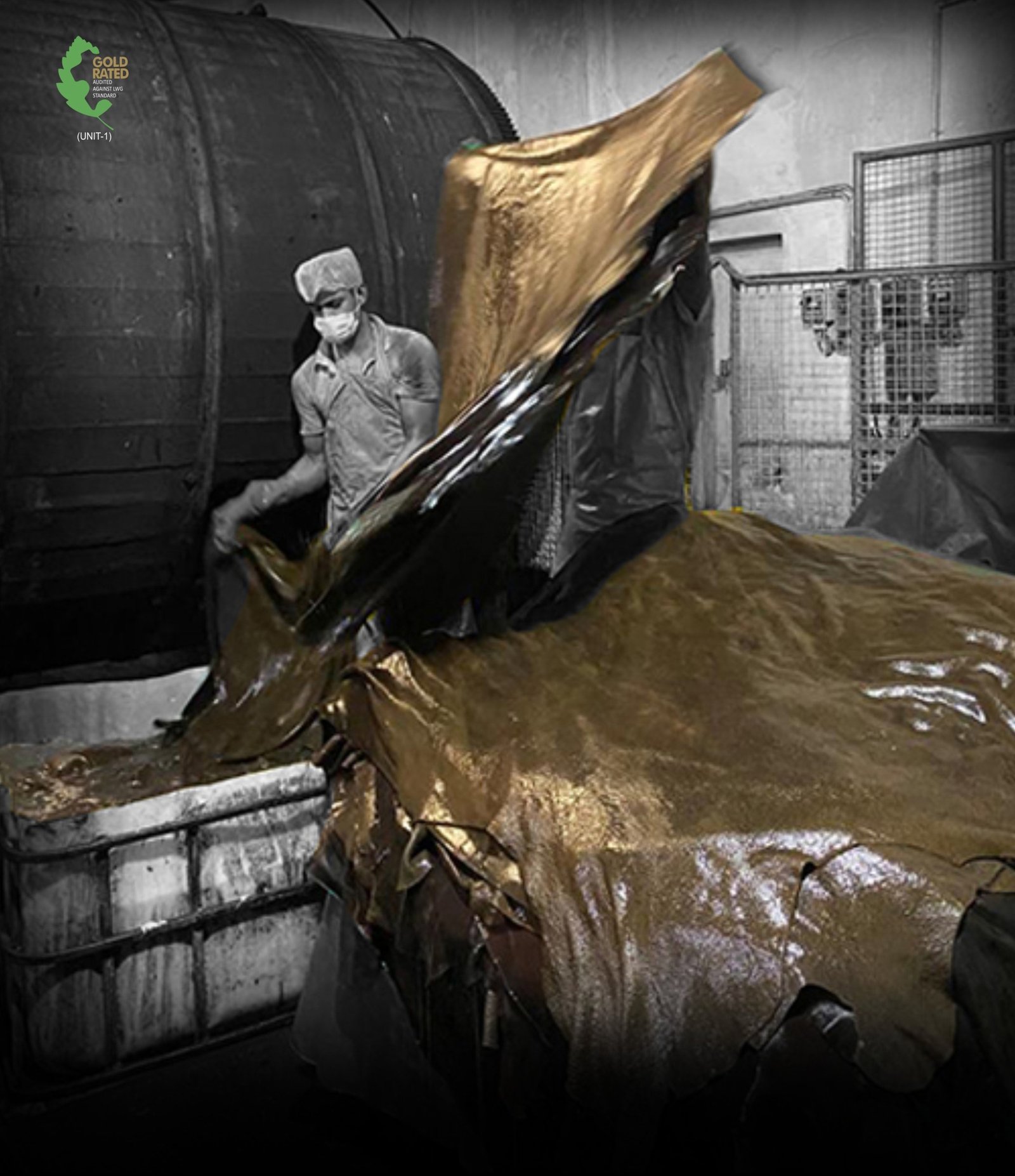

Leather dyeing Process

The wet blue hides are then dyed to color per order,Hides are dyed in large drums with dyes and fat liquors to set color,hand and softness,

In-house chemical testing lab

This lab plays a crucial role in quality control and assurance. It helps in assessing the composition, purity, and characteristics of chemicals used in the processing of leather. It may also conduct tests to verify compliance with industry standards and regulations.

Pure environmental logical thinking Tannery

Our production process involves integrating environmental thinking into production to analyze how much resources are used for manufacturing. Usage of energy and requirements for transportation…..

![]()

Tannery Email :

sales@flamingossi.com

Telephone:

Mobile :+91 98 409 33 207